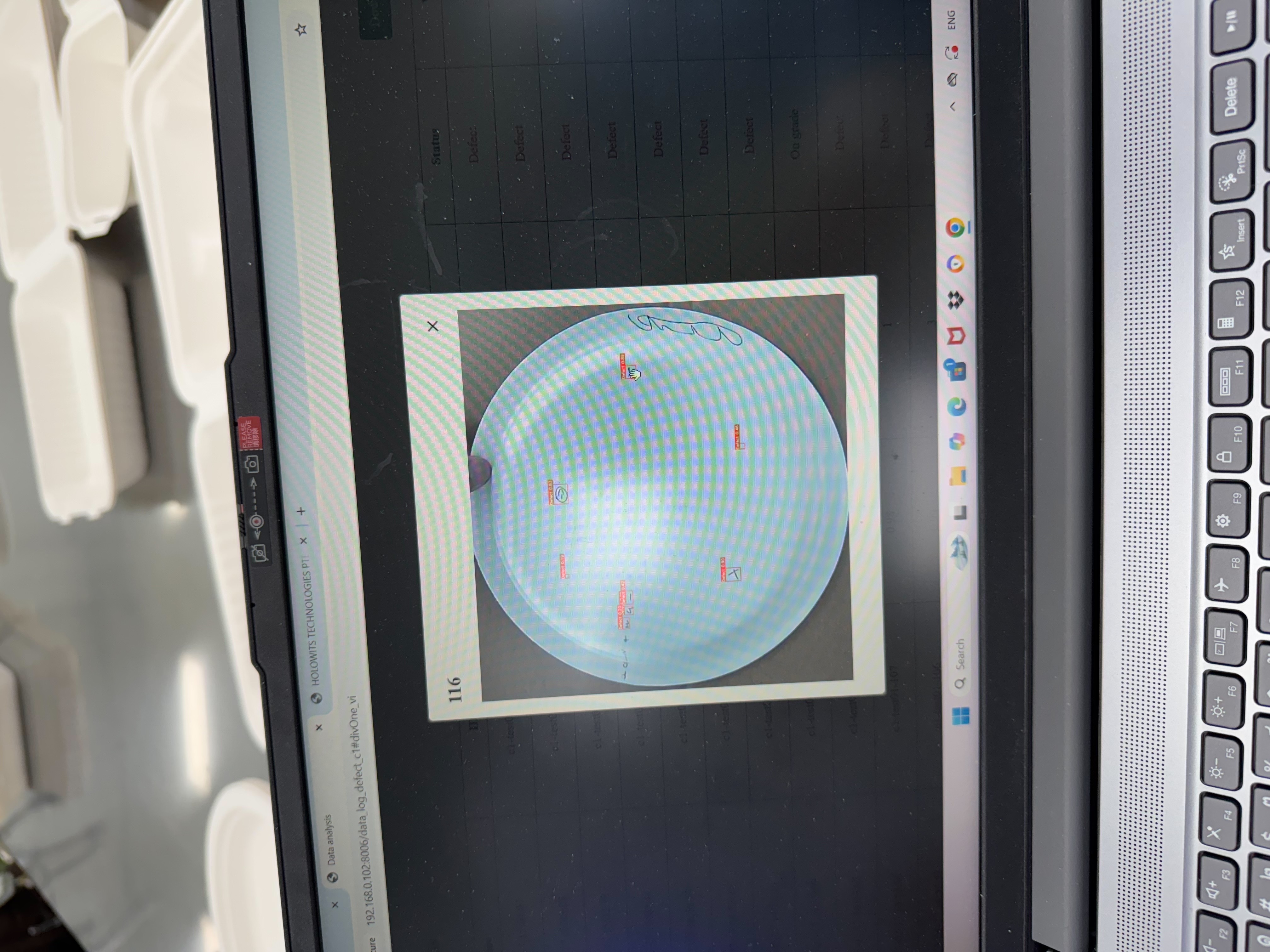

Intelligent Defect Detection

Comprehensive Plate-Type

Real-Time Visual Inspection

Extensive Defect Coverage

Scalable AI Inspection Platform

Labor Cost Reduction & Process Efficiency

Intelligent Defect Detection

AI-powered system that automatically identifies various defects on paper plates—including tears, stains, black spots, water marks, or tiny contaminants—improving inspection accuracy while reducing human labor dependency.